Rubber Flooring

Rubber Flooring

Puzzles and platforms manufactured with recycled rubber that guarantee a perfect shock-absorption, besides a smooth and easily cleanable surface.

We classify technical rubber flooring according to two different types:

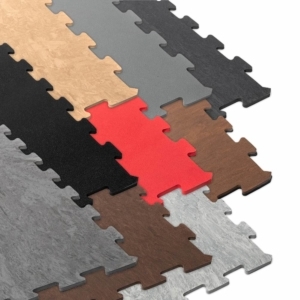

1) New rubber, produced by molding. Models: Outrace and EcoFit.

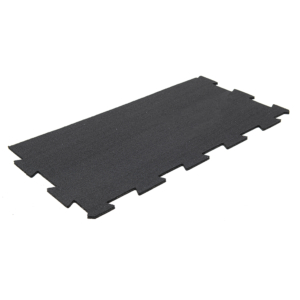

2) Recycled rubber, produced by the agglomeration of granules, models: EcoGym.

Floors of the first type, produced by molding new rubber, have a higher production cost but have a series of important qualitative characteristics. The first feature is aesthetics. The tiles are extremely finished, with precise edges and joints and with a very wide range of colors, with different solutions with a high visual impact. The type of product also allows the insertion of colored graphic elements in such a way as to obtain markers, drawings, customized logos, lasting over time; precisely because they are obtained from the insertion of rubber into the tiles and not from the overlapping of adhesive elements. The second important feature is its compactness. The tiles produced by hot pressing have a very dense rubber, therefore suitable for areas dedicated to free body exercises and extremely suitable for rooms equipped with isotonic and cardio machines, tools that require high stability. The third feature is hygiene. The compactness of the rubber prevents the absorption of dirt, water and sweat, making cleaning the surface easy and effective. Fourth characteristic is the smell. New rubber is essentially odorless. Fifth characteristic is the reaction to fire; fire retardant additives make the Cfl-s2 classification possible. Finally, sixth but not least, durability. The density and compactness of the rubber mean that the surface does not wear out and come apart quickly due to use, also depending on the sliding of the wheels of the benches.

The floors of the second type, produced with an agglomeration of recycled rubber granules, have had a great diffusion thanks to the success of Crossfit® and functional training, due to some extremely characteristic technical specificities, to the point of subordinating any qualitative limit.

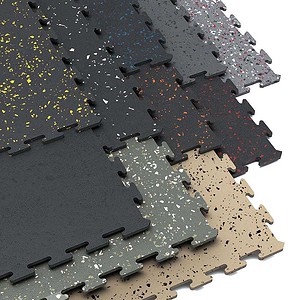

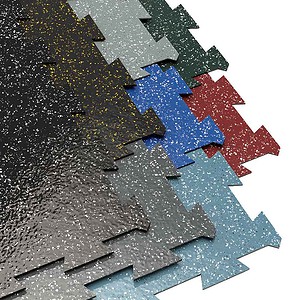

The rubber of these tiles does not form a single element but is granular, that is, composed of grains of rubber pressed together and joined by the action of chemical binding agents. By increasing the size of the grains, more grainy tiles are obtained and more able to absorb energy. The great ability to absorb shocks and resist tearing / incisions from falling tools is in fact the main feature of this type of flooring and the reason for its success in areas where free weights can fall to the ground. The second feature is that it is extremely non-slip. Being granular, even in the presence of a lot of liquid the grip remains unaltered, which is ideal for areas dedicated to high-intensity training where athletes, dispersing a lot of sweat, can create situations of high slipperiness and danger. The third feature is the cost. The tiles produced using agglomerate of recycled rubber granules have low production costs and this is also consistent with the function of resisting the fall of tools which can also involve the need for replacements. Finally, aesthetics. As spartan flooring, an icon of areas dedicated to intense training, this type of tiles have become striking and distinctive also from an aesthetic point of view, especially in the black color.

In the face of these outstanding qualities, however, flooring made of recycled rubber granules has some limitations. First the finishing. The granular structure does not allow precise edges and joints and the creation of a wide range of colors. According to hygiene. The porous surface makes cleaning less simple. The third limit is the smell. Recycled rubber, even if selected, is not as odorless as new but becomes so after a few weeks of installation. Fourth is the reaction to fire with Efl classification. The fifth limit is durability. Absorbing shocks and being highly non-slip cause the surface to wear out and flake more than non-granular tiles.

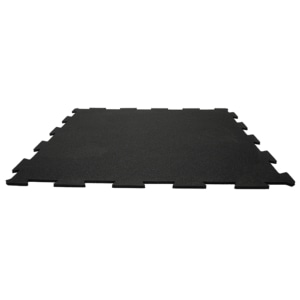

In order to reduce these limits, Ecogym is made of a double layer, large granules below, for shock absorption, fine granules above, to reduce porosity. A solution that makes the product not comparable to other similar floors as the level of finishing, jigsaw puzzle, and hygiene are absolutely superior. Hygiene also due to the fact that the tiles do not have edges with rounded corners, but the double-layer solution allows you to create sharp corners thus avoiding large gaps to collect dirt between the tiles. Finally, a careful selection of recycled rubber allows to minimize the smell of the tiles. The platforms for weight lifting are made with this second type of rubber: Ecogym.